PRODUCT PERFORMANCE

Information on BS EN 1953 - a European standard for the classification of the strength and durability of side hung metal hinges. CE - For hinges used on fire or escape routes. Certifire - Certification for fire protection products. The Equality Act 2010 concerned with giving access to all. Door to frame clearances, adjusted door weights, hinge positioning and number of hinges and Care & maintenance.

BS EN 1935

This is the European standard for the classification of the strength and durability of side hung metal hinges. Hinges are tested against a standard door and number of cycles to achieve certification. A single hinge is tested, whereas in reality a minimum of three hinges will support the door. The chart below shows the various grades.

| Hinge Grade | Usage | Test Cycles | Door Mass |

|---|---|---|---|

| 1 | Window | 10,000 | 10 kg |

| 2 | Window | 10,000 | 20 kg |

| 3 | Window / Door | 25,000 | 20 kg |

| 4 | Door | 200,000 | 20 kg |

| 5 | Window | 10,000 | 40 kg |

| 6 | Window / Door | 25,000 | 40 kg |

| 7 | Door | 200,000 | 40 kg |

| 8 | Window | 10,000 | 60 kg |

| 9 | Window / Door | 25,000 | 60 kg |

| 10 | Door | 200,000 | 60 kg |

| 11 | Door | 200,000 | 80 kg |

| 12 | Door | 200,000 | 100 kg |

| 13 | Door | 200,000 | 120 kg |

| 14 | Door | 200,000 | 160 kg |

Hinges that are used on fire or escape routes must legally be CE marked. The mark on the product will satisfy building inspectors and trading standards officers that you have done your best to ensure that the building is safe to use. Increasingly it will become the duty of the building owner to ensure that the building is safe to use and this is where CE marked products can help.

CE marking is not easily achieved. Products have to be checked at independent test laboratories and the production is checked within the manufacturing factories. To keep your building safe only use products with this mark.

CERTIFIRE is voluntary third party certification for fire protection products, operated by Warrington Certification. CERTIFIRE tests a huge range of hardware products. CERTIFIRE approved products will all work together on the door assembly to ensure maximum safety against spread of fire. CE marked products do not have the same rigorous certification requirements as CERTIFIRE approved products so to remove any doubt of your chosen hinge and door closer working together on your door assembly make sure that they are both CERTIFIRE approved.

See our CERTIFIRE certificate CF351 for details of products and their fire test cover on www.warringtonfire.net.

DDA

The Disability Discrimination Act 1995 (DDA), is concerned with giving access to all to buildings. The more noticeable changes to buildings are the increasing numbers of disabled toilets. DDA is equally concerned about the ease of opening doors for wheelchair users and for this reason has specified the maximum opening forces for doors. Fire regulations demand all fire doors to close shut to prevent the spread of fire and though they take precedence over DDA can conflict with the DDA requirements. One way of ensuring that doors open easily for wheel chair users and also close to prevent the spread of fire is to use hinges with the lowest possible torque resistance. The European standard for hinges BS EN 1935 allows a maximum of 4Nm resistance to opening whereas the high quality bearings used in Phoenix high performance hinges will typically operate at less than a 1Nm resistance.

Adjusted Door Weights

The reliability of the hinges depends on several factors, door width and type of door closer being two important factors. Adjusted door weights for doors fitted with door closers are covered by Step 2 earlier in this guide. For doors of excessive width (1000mm or more) further adjustments need to be made to allow for the increased bending moment acting on the hinges.

| Door Width (mm) | Theoretical Increase in door mass % |

|---|---|

| 1000 | 0 |

| 1050 | 10 |

| 1100 | 18 |

| 1150 | 26 |

| 1200 | 33 |

| 1250 | 40 |

Door Weights

The chart below provides the mass ranges of typical doors. Doorset manufacturers data or weighing scales should be used to accurately assess the door weight.

| Mass ranges of typical doors | Size (mm) | Mass (kg) |

|---|---|---|

| Cupboard, wardrobe, cabinet louvred doors and shutters | 2040 x 626 x 40 | 3 to 10 |

| Light internal large wardrobe and large louvred doors | 2040 x 926 x 40 | 10 to 17.5 |

| Medium internal doors | 2040 x 1012 x 40 | 17.5 to 25 |

| Heavy internal doors | 2040 x 1012 x 40 | 25 to 37.5 |

| Half hour fire doors | 2040 x 826 x 44 | 25 to 37.4 |

| Light external doors | 2040 x 907 x 40 | 20 to 37.5 |

| Heavy external doors | 2040 x 1002 x 44 | 37.5 to 55 |

| One hour fire doors | 2040 x 826 x 54 | 37.5 to 72.5 |

| Oversize or special external doors | 2400 x 1200 | 55 to 110 |

Ironmongery

The weight of the ironmongery also places a load on the hinges. The allowances are shown in the table below.

| Typical weight of ironmongery (kg) | General | Aluminium | Stainless Steel |

|---|---|---|---|

| Pair of lever handles | 0.7 | 0.4 | 1 |

| Kickplate 900 x 200 x 1.5 (pair) | 3 | 1.5 | 4 |

| Heavy duty door closer | 3 | - | - |

| Economy door closer | 2 | - | - |

| Euro pattern lock 72mm ctrs | 1 | - | - |

| English pattern lock 57mm ctrs | 0.5 | - | - |

Hinge Classification

CE digit classification in detail

First Digit - Category of use:

There are four categories 1-4:

Light duty: Low frequency of use by people with a high incentive to exercise care and with only a small chance of accidents occurring or of misuse.

Medium Duty: Medium frequency of use by people with some incentive to exercise care but where there is some chance of accidents occurring or of misuse.

Heavy duty: High frequency of use by public and others with little incentive to exercise care and with a high chance of accidents occurring or of misuse.

Severe duty: For use on doors that are subject to frequent violent usage.

Second Digit - Durability:

Durability of hinges is classified into one of four categories of use; two are for windows and two for doors. Hinges for doors are tested to 25,000 and 200,000 cycles, whilst this may not seem to be many cycles when compared with the numbers in the annual usage table it must be remembered that the hinge test equipment in the standard applies the full test loads to one hinge and this greatly accelerates the actual wear in real use. The table on the next page shows the typical frequency of doors in use, the durability requirements and a subjective category of use.

Third digit - Test Door Mass:

Currently there are eight weight grades for the test door though this will potentially be increased in future issues of the standard. The grades start at 10kg and go up to the maximum of 160kg.

Fourth Digit - Fire Behaviour:

Grade 0: not approved for use on fire/smoke resisting door assemblies, Grade 1 is suitable for use on fire/smoke resisting door assemblies. This 0 or 1 grading is likely to be superseded in revisions to standards, giving greater detail of exactly what fire rating was achieved. All fire tests must be carried out to EN1634.

Fifth digit - Safety:

Only grade 1 hinges are acceptable. Grade 1 hinges meet the essential requirements of safety in use, which forms part of the Construction Products directive (89/106/EEC)

Sixth digit - Corrosion Resistance:

There are five grades of corrosion resistance ranging from 0 to 4.

- Grade 0 no corrosion resistance

- Grade 1 mild resistance

- Grade 2 moderate resistance

- Grade 3 high resistance

- Grade 4 very high resistance

Corrosion testing is carried out in accordance with the test methods outlined in EN 1670

- Grade 0 - No defined corrosion resistance

- Grade 1 - 24 hours salt spray resistance

- Grade 2 - 48 hours salt spray resistance

- Grade 3 - 96 hours salt spray resistance

- Grade 4 - 240 hours salt spray resistance

Seventh Digit - Security:

Two grades are identified. Grade 0 is not suitable and Grade 1 is suitable for security doors.

Eigth Digit: - Hinge Grade

Fourteen grades are identified within the standard, which are shown earlier under the BS EN 1935 classification.

Frequency of Door Operation

| Type of building and door | Estimated Frequency | Category of Use | Durability | |

|---|---|---|---|---|

| Daily | Yearly | |||

| Entrance to department store | 5,000 | 1,500,000 | S | 7 |

| Entrance to large office | 4,000 | 1,500,000 | S | 7 |

| Entrance to school | 1,250 | 225,000 | S | 7 |

| School toilet | 1,250 | 225,000 | S | 7 |

| Entrance to Bank | 500 | 150,000 | H | 7 |

| Office toilet | 400 | 120,000 | H | 7 |

| School corridor | 80 | 24,000 | M | 7 |

| Office building corridor door | 75 | 22,000 | M | 7 |

| Department store toilet | 75 | 22,000 | M | 4 |

| House entrance | 40 | 14,000 | M | 4 |

| House toilet | 25 | 7,500 | L | 4 |

| House corridor | 10 | 3,000 | L | 4 |

Fire Doors

| Class | Approved door type | ||||||

|---|---|---|---|---|---|---|---|

| Type of building and door | IMM | MM | TT | ITT | ITM | ITC | TM |

| FD20 |

|

|

|

|

Consult technical sales for advice on all options not covered by a tick within the matrix | ||

| FD30 |

|

|

|

||||

| FD60 FD120 FD240 |

|

|

|||||

| E20 E120 |

|

|

|

|

|||

| E30 E130 |

|

|

|

||||

| E60 E160 E90 |

|

|

|||||

| EI 90 E120 EI120 |

|

|

|||||

| E240 EI240 |

|

|

|||||

Abbreviations

IMM - Metal leaf, Metal frame and intumescent seals

MM - Metal leaf, Metal frame

TT - Timber leaf, Timber frame

ITT - Timber leaf, Timber frame and intumescent seals

ITM - Timber leaf, Metal frame and intumescent seals

ITC - Timber leaf, Composite frame and intumescent seals

TM - Timber leaf, Metal frame

Door to Frame Clearances

The majority of architectural hinges are designed to be rebated flush into the door and frame. The gap when the hinge is closed to the parallel leaf position should therefore match the recommended clearance between door and frame. On steel doorsets this is usually set by the manufacturer. On timber doorsets the following guidelines can be used:

3mm for doors fitted with a combined intumescent and smoke seal. 2.5 - 3mm for doors fitted with intumescent only.

For doors which are not fire doors the recommendation is for a consistent clearance between door and frame within the range of 1.5 to 3mm

Hinge Positioning

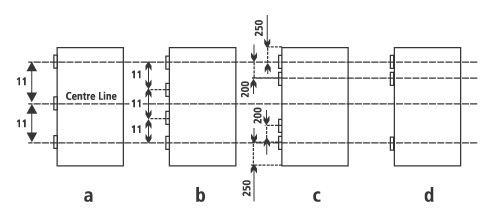

On doors without door closers it is usually recommended to use three hinges, the top and bottom hinges being fitted approximately 250mm from the door end to the hinge centre, with the third hinge being positioned in the centre of the other two. Equally spaced hinges will minimise warping which may occur with extremes of temperature or humidity on either side of the door, Fig.1, a and b.

Unequally spaced hinges Fig.1, c and d, improve load bearing. This is recommended where the hinges are operating near their load bearing maximum or where door closers, particularly back check door closers, are in operation and the door is in high frequency use.

Hinge numbers

BS 4787 pt 1 states that normally three hinges are fitted to a door leaf but for doors exceeding 2100mm in height a fourth hinge should be fitted, and that this should be positioned about 200mm below the top hinge.

Care and Maintenance

Architectural hinges play an important part in the overall performance of any building. All the Phoenix architectural hinge ranges are designed to give many years trouble free use with only the minimum of routine maintenance when selected in accordance with the guidelines in this product selection brochure and as stated on the fitting instructions leaflet. In order that hinges continue to operate at maximum efficiency they should be checked annually:-

- Ensure all fasteners are secure.

- Where necessary wipe clean with a solution of mild detergent applied with a soft damp cloth. Do not use abrasives or bleach as this may permanently damage the hinge surface and its components.

- Where regular lubrication is recommended re-lubricate the hinge pin and bearings using a light oil, ideally in aerosol form such as WD40 or Tri-Flo which can penetrate into the hinge internal areas.

- Check that no additional strains are present upon the door caused by building movement or due to warping of the door or frame. This can result in the hinges being put under severe additional loadings. Where problems of this nature occur then the cause of the problem needs to be eliminated, and the hinges re-fitted.

Phoenix Architectural Hinges - Guarantee

All the Phoenix architectural hinge ranges come with a performance guarantee based on EN 1935 test results. Each range is guaranteed for a maximum period as shown on the chart, and up to a maximum number of cycles, being the annual recommended maximum as shown on the chart times the number of years of the guarantee, whichever occurs first.

Replacement contribution is of the equivalent current hinges supplied to the distributor's UK base in proportion to the remaining period / usage of the warranty still outstanding, and is subject to confirmation that the hinges have been correctly specified, fitted and maintained as outlined in this brochure and on the fitting instructions supplied with the products.